Your Doctoring partner

Your Doctoring partner

Your Doctoring partner

Your Doctoring partner

Because it has a direct impact on the efficiency of the machine, improved doctoring equals greater machine production efficiency

Because it has a direct impact on the efficiency of the machine, improved doctoring equals greater machine production efficiency

Higher machine speed

Higher machine speed

Fewer machine shutdowns

Fewer machine shutdowns

Fewer paper breakages

Fewer paper breakages

Because it can be an inexpensive way to increase machine efficiency: changing the type of blade requires neither investment nor financing

Because it can be an inexpensive way to increase machine efficiency: changing the type of blade requires neither investment nor financing

Because cleaner rolls produce higher quality paper

Because cleaner rolls produce higher quality paper

Because more sophisticated materials can reduce energy consumption

Because more sophisticated materials can reduce energy consumption

Because more sophisticated materials can mean longer life for the roll coating

Because more sophisticated materials can mean longer life for the roll coating

Because more sophisticated materials can reduce the cost of the blades per ton produced

Because more sophisticated materials can reduce the cost of the blades per ton produced

Because fewer blade changes reduces the risk of accidents for the operators

Because fewer blade changes reduces the risk of accidents for the operators

Because more sophisticated materials can reduce energy consumption

Because more sophisticated materials can reduce energy consumption

Because more sophisticated materials can mean longer life for the roll coating

Because more sophisticated materials can mean longer life for the roll coating

Because more sophisticated materials can reduce the cost of the blades per ton produced

Because more sophisticated materials can reduce the cost of the blades per ton produced

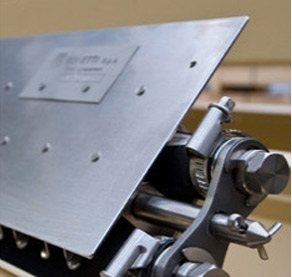

Optimization of system

Optimization of system

Linearity of the system

Linearity of the system

Bearing conditions

Bearing conditions

Alignment of the systems

Alignment of the systems

Linearity of pressure plate of the holder

Linearity of pressure plate of the holder

Oscillations and drive

Oscillations and drive

Roll surface conditioning

Roll surface conditioning

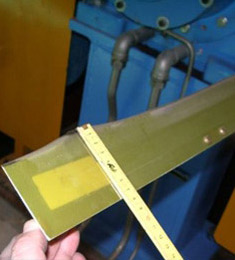

Blade wear analysis

Blade wear analysis

Bevel Geometry variation analysis

Bevel Geometry variation analysis

Roll surface roughness

Roll surface roughness

Levcon jaykay, has created Indian resources for services and installation of doctoring systems, trained by Bonetti. We are available for any kind of technical supervision during installation of doctoring systems and for their subsequent maintenance.